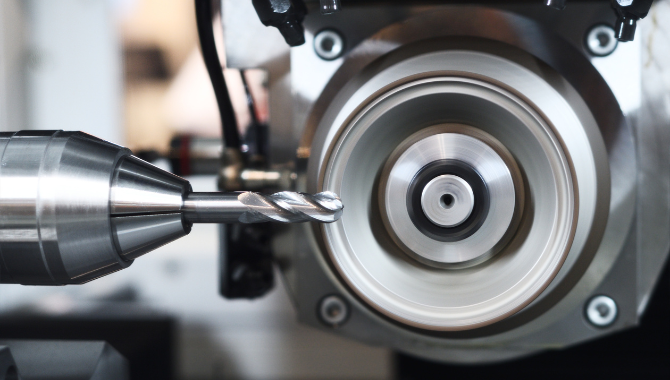

L’usinage CNC est généralement toujours la technologie de fabrication optimale pour obtenir les pièces en titane les plus précises et les plus économiques. La coupe et le façonnage de précision des composants en titane sont réalisés grâce à l’usinage CNC, qui utilise des machines contrôlées par ordinateur.

L’examen des alternatives nous aidera à comprendre pourquoi. Cet article couvre les principes fondamentaux de l’usinage CNC du titane, y compris les meilleures utilisations, les facteurs d’usinage et les choix de finition de surface.

Grades de titane pour l'usinage CNC

- Low-oxygen titanium for commercial use.

- Among the most frequently used titanium grades. This titanium alloy offers the highest ductility and flexibility.

- Teneur standard en oxygène, titane commercialement pur.

- Il est largement reconnu que le titane pur a une norme industrielle.

- Titane commercialement pur avec une concentration modérée en oxygène.

- Le grade 3 est le moins utilisé dans le commerce tout en ayant d’excellentes propriétés mécaniques.

- Le titane se caractérise par une teneur élevée en oxygène et une pureté commerciale.

- Parmi les quatre qualités commercialement pures, il est considéré comme le plus solide.

- Alliage de titane, Ti6Al4V

- L’alliage de titane le plus couramment utilisé est celui-ci. Il contient 6 % d’aluminium et 4 % de vanadium.

- Ti5Al-2,5Sn est un alliage de titane.

- Il est le plus souvent utilisé dans les applications concernant les cellules d’avion et les moteurs à réaction.

- Ti-0.15Pd, un alliage de titane, est parfois considéré comme “pur”.

- Il est comparable au grade 2, mais avec un minuscule ajout de palladium pour augmenter la résistance à la corrosion.

- Ti-0.15Pd, un alliage de titane, est parfois considéré comme “pur”.

- Tolérance plus faible pour les contaminants supplémentaires, similaire au grade 7.

- Ti0,3Mo0,8Ni est un alliage de titane.

- Cet alliage extrêmement résistant contient 0,8 % de nickel et 0,3 % de molybdène.

- Le T6Al4V-ELI est un alliage de titane.

- Sur le marché, il est également appelé TAV-EIL (Extra Low Interstitial). Bien que plus pur, il est comparable au grade 5.

The Main Advantages of Titanium Parts with CNC Machining

Durability and Portability: Titanium has an outstanding ratio of strength to weight.

Resistance to Corrosion: Submarines and maritime equipment made of titanium can be found submerged in the world’s lowest waters.

Compatibility with biological systems: Many people now have hope due to prostheses and medical implants made possible by titanium’s biocompatibility.

Heat-Resilient Resilience: Extreme temperatures are encountered by rocket motors and jet engines.

Regarding Costs: Titanium is not cheap. However, considering its durability, endurance, and potential to outlive alternatives, it offers cost savings in numerous long-term applications.

Practical Guidance Regarding Titanium Machining

Firmly Attach the Parts

- Since tool chatter is a normal occurrence with titanium, any vibration reduction will make titanium machining simpler.

Appropriate Selection of Cutting Tools

- With the demand for titanium growing, toolmakers are developing new techniques to improve titanium’s machinability.

Evaluation of the Cutting Requirements

- A constant, high-pressure coolant source directed at the area being cut is one of the easiest methods to keep the workpiece and tools cold.

Machined Surfaces Made of Titanium with Different Finishes

Titanium objects that have been CNC-machined can have their appearance or utility improved by using a variety of surface finishing procedures.

- Smoothing

- Polishing

- Bead blasting

- Brushing

- Painting

- Chroming

- Metalizing

- PVD coating

- Powder coating

- Electrophoresis

Increased Galling and Chemical Sensitivity

Titanium alloys may react with various gases during machining, resulting in problems including surface oxidation and embrittlement.

A Rise in Temperature and Cutting Pressure

Since titanium has a limited heat conductivity, rapid tooling causes heat to build up in the metal workpiece.

Stresses that Persist and Become Harder

Titanium alloys’ relatively low degree of flexibility stems from their crystal structure, which could present problems while machining.

Carbon fiber inserts – Given their great wear resistance and toughness, these are the most often used cutting tools for titanium machining.

Tools made of High-Speed Steel (HSS) – Compared to carbide inserts, these tools are less expensive and appropriate for smaller machining jobs.

Ceramic inlay systems – These are appropriate for high-speed titanium machining since they are extremely durable and heat-resistant.

Tools made of polycrystalline diamonds (PCD) – Incredibly durable and wear-resistant and can be used for high-precision titanium machining.

Not magnetic: It has no magnetic properties.

Not dangerous: Titanium is a great material to utilize in the medical field because of its high biocompatibility, and non-toxicity.

Robustness: Titanium is an exceptionally robust material that performs well in CNC-machined parts.

Grade 5 titanium, or Ti6Al4V, is a material that is frequently used in CNC machining.

- Think About the Cutting Tool’s Flutes

- Keep Your Blade Sharp and Steer Clear of Interrupted Cuts

- Consider Cutting Tool Coating

- Use High-Feed Mills for Machining Titanium

Among the CNC machining processes employed are milling, turning, drilling, and tapping.

Titanium materials can be precisely and intricately shaped with the use of these processes.

Though titanium is more expensive, CNC machining of titanium is still appropriate for prototypes.

The utilization of CNC machining facilitates the precise and consistent construction of prototypes featuring intricate geometry.

Typical post-machining methods to guarantee the quality and integrity of the machined titanium parts are as follows:

- Making use of heat

- Surface finishing techniques include passivation and anodizing.

- As well as methods of examination.

Numerous variables, including the following, might affect the price of CNC machining titanium:

- The intricacy of the part

- Quantity

- Required toleration

- Volume of Production

- And grade of titanium